INTERNATIONAL JOURNAL OF FATIGUE Volume 136, July 2020, 105581

Pedro R. da Costa, Henrique Soares, Luís Reis, Manuel Freitas(doi;10.1016/j.ijfatigue.2020.105581)

Ultrasonic fatigue testing is a relative recent fatigue study methodology that applies resonant principles for the induction of stress cycles in a specific designed material specimen. Such experimental method can apply fatigue damage at high frequencies, most commonly at 20 kHz. It was created with the main purpose of studying material fatigue life in the Very High Cycle Fatigue regime between 10E07 and 10E09 cycles with a higher performance of time and energy wise in comparison to conventional servo-hydraulic machines.

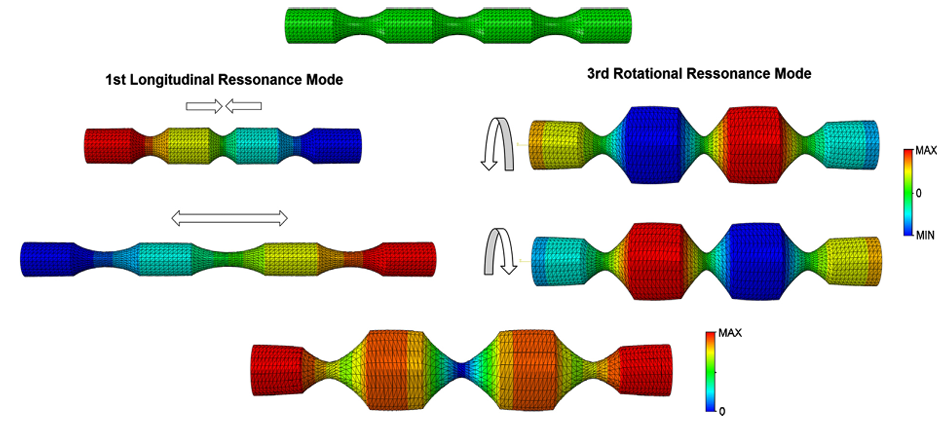

In this study an ultrasonic fatigue testing machine was used in order carry out multiaxial tension/torsion fatigue tests at a frequency of 20 kHz. The main objective was to reach a reliable multiaxial fatigue testing method, by modifying only the specimen, with the ability to choose the shear-axial stress ratio.

The improved design of the testing method was focused in innovative design specimen by conducting both numerical and experimental analysis. Thermographic imaging, laser displacement measurements, and the application of rosette strain gauges to the main stress region of the specimen were carried out in order to validate the new improved design concepts. These strain and displacement results were compared with the ones obtained by finite element and a good agreement was achieved.

A first series of fatigue tests were carried out intension/torsion multiaxial fatigue and the results are discussed in order to understand the feasibility of multiaxial fatigue tests at ultrasonic frequencies.